New procedure for the maintenance in the electric substations of interiors to achieve their operational efficiency

Nuevo procedimiento para el mantenimiento de las subestaciones de interiores para lograr su eficiencia operacional

Carlos Manuel Ruano-González1

Fecha de recepción: 24 de enero, 2024

Fecha de aprobación: 2 de junio, 2024

Ruano-González, C.M. New procedure for the maintenance in the electric substations of interiors to achieve their operational efficiency. Tecnología en Marcha. Vol. 38, No 1. Enero-Marzo, 2025. Pág. 68-77. https://doi.org/10.18845/tm.v38i1.7037

https://doi.org/10.18845/tm.v38i1.7037

Keywords

Diagnostic; half tensión; generalities of the maintenance; new procedure; indicators of world class

Abstract

The electric substations of half tension are fundamental parts of the groups of distributed generation, which play an important paper in the readiness of the Electric System of Powers. These for their nature, it changes the conception when analyzing the maintenance techniques regarding those that know each other traditionally or usually used in the conventional substations of external, for what the administration of a methodology for its realization should be well conceived and based. On this work line he/she goes the analysis and conception from the maintenances to the electric cells that conform a substation of half tension of interiors that you/they are used in the groups of distributed generation. Where to carry out the maintenances, the methods and procedures are used applied to the substations of external in their great majority, based on the application of the preventive maintenance, after analysis and studies carried out by the frequent mishaps that you happens, committing the electric power service to the users and existing damages to the primary teams that compose the electric cells, becomes necessary to implement a methodology for the diagnosis and the administration of the maintenance, where other types of maintenances like the preventive ones and predictive are conjugated, we will use for their control and evaluation the maintenance to electric substations by means of indicators of world class, proposing a methodology that is able to improve their operational efficiency.

Palabras clave

Diagnostico; media tensión; generalidades del mantenimiento; nuevo procedimiento; indicadores de clase mundial.

Resumen

Las subestaciones eléctricas de media tensión son partes fundamentales de los grupos de generación distribuida, los cuales juegan un papel importante en la disponibilidad de los Sistema Eléctrico de Potencias. Estas por su naturaleza, cambia la concepción a la hora de analizar las técnicas de mantenimiento respecto a las que se conocen tradicionalmente o usadas normalmente en las subestaciones convencionales de exteriores, por lo que la gestión de una metodología para su realización debe estar bien concebida y fundamentada. Sobre esta línea de trabajo se dirige el análisis y concepción de los mantenimientos a las celdas eléctricas que conforman una subestación de media tensión de interiores, que se utilizan en los grupos de generación distribuida. Donde para realizar los mantenimientos, se utilizan los métodos y procedimientos aplicados a las subestaciones de exteriores en su gran mayoría, basado en la aplicación del mantenimiento preventivo, después de análisis y estudios realizados por las frecuentes averías que se suceden, comprometiendo el servicio de energía eléctrica a los usuarios y existiendo daños a los equipos primarios que componen las celdas eléctricas, se hace necesario implementar una metodología para el diagnóstico y la gestión del mantenimiento, donde se conjuguen otros tipos de mantenimientos como los preventivos y predictivos, utilizaremos para su control y evaluación el mantenimiento a subestaciones eléctricas mediante indicadores de clase mundial, proponiendo una metodología que logra mejorar su eficiencia operacional.

Introduction

Due to the constant interruptions, more the problems so much economic as social, including the affectations to the environment and the security of the human capital that can cause the flaws of the cells that conform the electric substations of the groups of Distributed Generation, makes imperative the search of alternative of solution to this problem, using technical of maintenances and diagnostic that are effective in the moment of their application.

The electric substations of interiors, associated to the distributed generation, independently that in a conceptual way they complete the same objective that the electric substations of external, have their particularities in their design that makes that the conception of their diagnosis and maintenance, they should have other considerations regarding the substations of external traditionally employees, for this reason it is of supreme importance to count a methodology for the diagnosis and the administration of the maintenance, appropriate to avoid the frequent mishaps that commit the electric power service to the users and to guard against damages to the primary teams that compose the electric cells.

The maintenance according to the Institute of Electric and Electronic Engineers (IEEE for their initials in English) it is not more than the act of to preserve or to maintain the conditions of a team for their correct operation, that is to say, the combination of all the technical and administrative actions that they include supervision actions that can maintain or to restore the state for which fulfills the functions tunes to their acting a team or certain system (IEEE Std C37.10, 2011) [1], the objective of the administration of the maintenance to the electric substations of half tension of interiors, is to assure the maximum dependability and readiness from the cells to low costs so that they fulfill its operative functions inside a context operational, preventing or correcting, when it is necessary, condition that they put in risk the operation of the same ones and of the installation to the one that are associate, as well as to the teams and neighboring facilities.

On the other hand, according to more recent investigations carried out by groups of work of the International Council in Big Electric Systems of High Tension (CIGRE for their initials in French) [2], he thinks about that inside the outlines of more used maintenances they are the preventive maintenance in 55%, this generally consists on to recondition or to substitute to regular intervals a team or their components, independently of their state in that moment, those intervals are established by the makers based on previous experiences, however, the investigations demonstrate that the effectiveness of these methods is strongly linked to the frequency of the maintenance inspections, and in the case of the electric cells many of the flaws that happen are not simply detected for it is necessary to use other techniques non to invade that you/they help to determine its state. The maintenance based on the condition represents 8% and 37% the combination of both.

The design was developed under a descriptive qualitative focus using the methodology of case study in a group of Distributed Generation with fuel oíl HYUNDAI of 40 MW, the same one is compound for four batteries conformed with four motors of the type HSR77198P of 2,5 MW each one, each battery has a generation of 10 MW for a total of 40 MW whose a substation is conformed for:

•Transformers type KMO - 0542 of exit of the batteries of 12,5 MVA and 34.5/6,6 kV.

•Four electric lines of exit, one of bar connection and two connection exits with a substation of 110 kw of exit of plant of a Thermoelectric Power station.

Independently of to be electric substations of interiors and to be in a reduced space of metallic and acclimatized booths, penetration of polluting particles always exists as powders in suspension and soot that, before the condensation of the humidity, they cause, an abnormal condition of operation, arriving to discharges of tension among the energized parts or you activate of the teams and until to severe flaws for contamination with an appreciable flaw index. For the before exposed, a special attention has been paid to the techniques of diagnostic and maintenance of these substations. As the technologies advance a new focus it is also needed in the maintenance, for it the specialists created what is known now as the Maintenance To predict or Based in the Condition, the same one consists on to inspect the teams to regular intervals and to take action to avoid the flaws or the consequences of the same ones according to the condition. It includes the objective inspections so much (with instruments) and subjective (with the senses), as the repair of the defect (it fails potential), these techniques of the maintenance have had a certain advance in some primary teams of substations like they are the transformers of powers, but not the rest of the elements that you compose the fields in the substations of external and the electric cells of the substations of interiors.

The study of the art in the administration of the maintenances to the electric substations of half tension of interiors, refers to the application of technical and advanced tools in the environment of the electric engineering to improve the efficiency, quality and security of the maintenance operations. It is observed that in none of the studies, he has been carried out a deep analysis of the administration of the maintenance to avoid in some way the different flaws and mishaps registered in the electric cells, for that in spite of the gradual increase of the different scientific investigations and thesis related with the diagnosis and checkup of the technical conditions of the primary teams of substations, a hole is denoted in the studies carried out in the world with respect to the administration of the maintenance of the electric substations of half tension of interiors.

Methodology

Investigation methods

Theoretical methods

Historical: To know the most common methods developed in the realization of the administration of the maintenances and diagnostic, from their emergence, evolution and development.

Analysis-synthesis: To analyze the primary components of the electric cells in an integral way and to understand their structure. In the synthesis they should unite the previously analyzed parts harmoniously, in order to reveal their relationships and general characteristics.

Systemic Method

To establish the relationship among the factors that intervene in the waste or aging of the primary teams

Statistical method

For the obtaining of the patterns of behavior of the state variables to validate it.

Existent assets [3], with a view to reducing the maintenance costs, to prevent the exits for emergency, and to achieve that the teams work a bigger term and in a surer way [4].

The monitor is the continuous and systematic process by means of which is verified the efficiency and the effectiveness of a product by means of the identification of its achievements and weaknesses and in consequence measured to correct is recommended to optimize the prospective results [5]. It is, therefore, condition for the rectification or deep of the execution and to assure the feedback among the objectives and theoretical budgets and the lessons learned starting from the practice. Also, it is the responsible one of to prepare and to contribute the information that makes possible to systematize results and processes, therefore, it is a basic input for the diagnosis.

So that the monitor is successful it requires of the establishment of a system of information, identifying the users of the information, the types of high priority information, linking the necessities and the sources of information, establishing appropriate methods to make the summary of data and to identify the necessary resources [6].

Generalities of the Maintenance

For each one of them, they are described their main ones next characteristic and definitions:

•Preventive maintenance: It is a group of activities (you inspect, tests, adjustments, repairs, taking of samples) regularly programmed and applied to the teams of a certain installation, in order to minimizing their degradation or loss of useful life.

•Maintenance predictive: It is a technique that consists regularly on monitor (followed than in the preventive maintenance) the key parameters of a team in operation, with the purpose of to detect and/or to correct a potential problem on time before the flaw of the team takes place.

•Maintenance corrective: When it is detected that the acting of some team begins to diminish and one shows off the possible causes of this first floor acting, it should be attacked to this causes and to carry out a maintenance of the team to avoid that the problem is increased.

•On the base of the obtained results of tests carried out to the electric team, the personnel responsible for the maintenance, has the enough arguments for to make the decision of maintaining energized or to move away of service a team in operation that requires maintenance, for the maintenance of the team, it is convenient to consider the following aspects:

•I file historical and analysis of results obtained in inspections and tests, is necessary also to consider the operative conditions of the teams, as well as the recommendations of the makers.

•To establish the maintenance necessities for each team.

•To formulate the activities of the maintenance programs.

•To determine activities with maintenance priority for each team in particular.

•He she should have specialized and competent personnel to carry out the maintenance activities to the team and to establish methods for their control.

A change of mentality is required in people and tools are used like:

•Engineering of the risk (to determine consequences of shortcomings that can be acceptable or not).

•Analysis of reliability (to identify feasible and profitable preventive tasks).

•It improves of the Maintenance (to reduce times and maintenance costs).

Results

Control and evaluation of the maintenance to electric substations by means of indicators of world class.

To know how efficient it is the planned maintenance politics’s application, it is needed to control and to evaluate the administration of the maintenance, this allows to act in a quick and precise way about the weak factors in the maintenance [7]. They should be carried out concise and specific reports, formed by charts of indicators and their respective graphics for some of these, these reports should allow an analysis easy and appropriate at each administration level, on the base of indicators of world class, called this way to be used and obtained in almost all the countries in the same way, of the six indicators of world class, four refer at the analysis of the administration of teams and two to the administration of costs. In this alone work one kept in mind three indicators of the first group, the indicative Half Time For Repairs (THFR) it is not analyzed, to refer to repaired teams. And they were carried out the calculations of the indicative Half Time Among Failure (TMEF), the three analyzed indicators are:

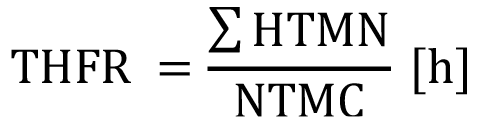

Half Time For Repairs (THFR): relationship among the total time of intervention correct in a group of elements with flaw and the total number of flaws detected in those elements, in the observed period, has the following expression:

(1)

(1)

Where:

HTMN: total time of maintenance (h).

NTMC: total number of flaws detected in the observed period.

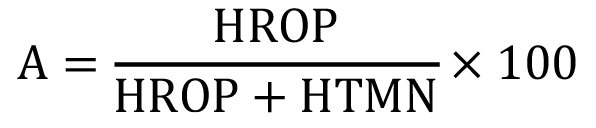

Available (A): percentage of the total time that the team was to disposition of the operation organ to carry out its activity.

(2)

(2)

Time Means Among Fails (TMAF): it indicates the interval of more probable time between an outburst and the appearance of a failure; that is to say, it is the time half lapsed until the arrival of the event failure. While adult is his value, adult it is the dependability of the component or team, he has the following expression:

Where:

NOIT: total of analyzed elements.

HROP: total time of operation (h).

On this work line he goes the analysis to the cells that conform the electric substation of the group of distributed generation, keeping in mind the indicators mentioned previously and carrying out the calculation of the one Time Means Among Fails (TMAF) and the generated databases of the administration of the maintenance applied to the reference substation, it is obtained that the time average among shortcomings taking as example a cell that you conform it seven primary elements has like average two flaws in the trimester.

When keeping in mind the indicators mentioned previously and the generated databases of the administration of the maintenance applied to this electric substation of the group distributed generation, where the time average among shortcomings (1) it is considered much smaller than the time average to consider it appropriate. To demonstrate it he takes as example a cell (cell 1) where electric elements of power is analyzed that conforms it, a switch of high tension, four mensuration transformers (three transformers of currents and a potential transformer), a lightning rod game and a bar switch all of a level of tension of 34,5 kV that he has like average two flaws in the trimester in some of the element that composes it, then applying the formula of time average among shortcomings has.

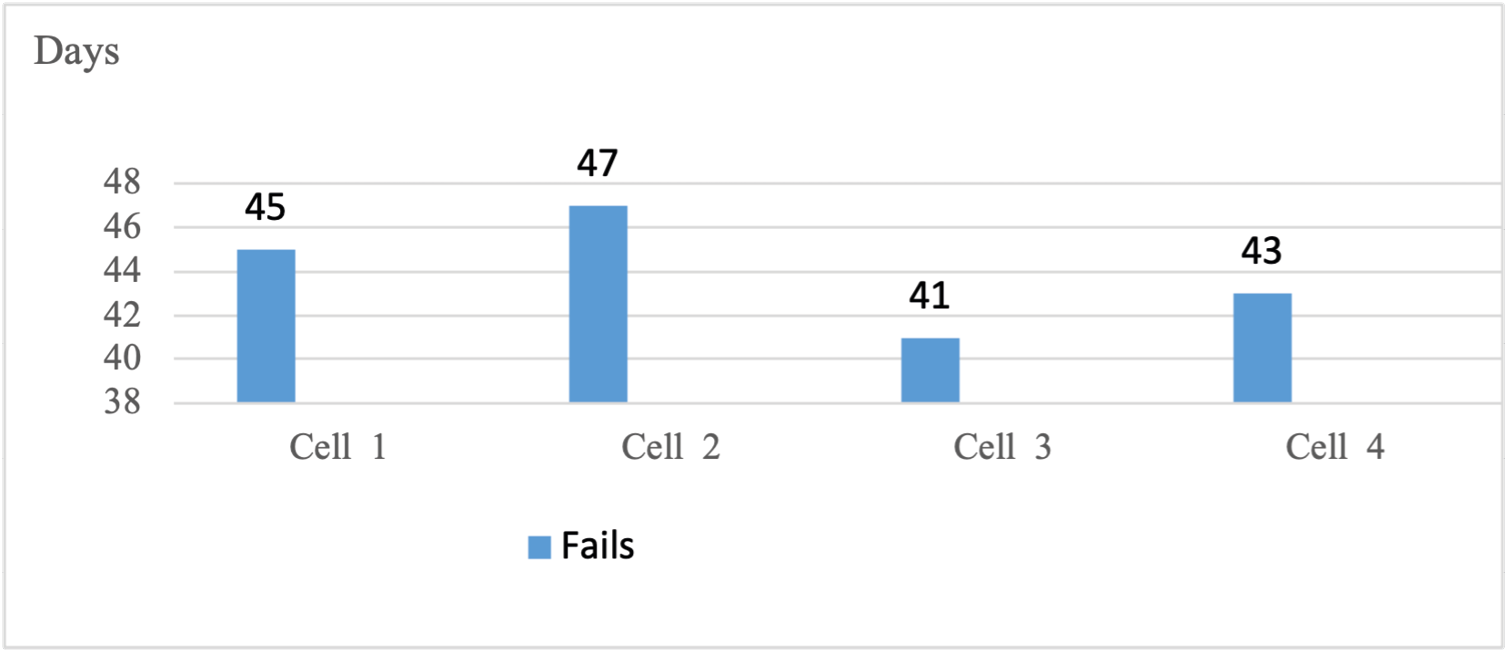

In the figure 1 are appreciated, by means of a graph of bars the obtained values of the half time among flaws for the cells 1, 2, 3 and 4, reflecting that the average among shortcomings in a cell is approximately of 44,25 days.

Figures 1. Time Means Among Fails (TMAF) for the first trimester of the year 2021. Source: [6].

When comparing the values of this indicator with some calculations carried out by the author in substations of external these they have given values of the half time among flaws many higher, where most of the elements begin to give signs of flaws or passed waste 90% of their useful life and others surpass their useful life without any problem and it is due to the correct application of the administration of the maintenance and the use of the techniques of diagnosis employees. For what the values goals of this indicator will depend on

New methodology

Methodology proposal for the maintenance to electric substations of 34, 5 kV used in the groups of distributed generation, the facilities of the groups for the distributed generation, even in these moments they play main list as complement of the generation it bases of the Electric System of Powers [8]., until it is not possible to modify the energy womb in the concerning thing to the electricity generation with renewable energy sources and keeping in mind the methodology from the maintenances to the electric substations of these facilities, they don’t present a to proceed and the standards are applied settled down in the procedure of the electric substations of external in most of the cases and when not existing any foreseen diagnosis activity [9] and keeping in mind that this type of electric substation presents a specific situation for its configuration, that they are conformed by cells inside a local acclimatized to a work temperature among 21 and 23 °C, which is not always completed and a total staunchness doesn’t exist that causes the accumulation of solids in suspension and soot that are deposited in the surfaces causing conduction between the active parts of the elements and earth. Existing jumps of potential not wanted that bear to flaws or exits outside of service of the electric cells, for what needs to diminish the frequency of verification of their bony parameters that the time between a maintenance or control of its parameters can vary, where a relationship of minimum time is looked for to carry out the intervention before it happens the mishap [10-11], this leaning with an action of diagnostic termografico once a week like he/she is carried out in the electric substations of exterior that it allows the i monitor of the condition [12].

This proposal is based on the experience of the exploitation, maintenances and attention of the mishaps in the electric substation of the Group of 40 MW of the Distributed Generation that according to the studies and due carried out analysis to the frequent flaws presented in the cells that compose the electric substation bear to implement a technique of diagnostic of infrared termografía that is possible to execute, since it is had the technology and the realization of maintenances in a smaller term of time [13].

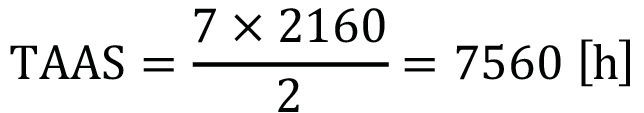

The indicators of administration of the maintenance once applied the new methodology, you can appreciate that it reaches a bigger dependability when diminishing the events of shortcomings or detection precociously their occurrence, which allows a better planning of the maintenance, in this case the events of observed failure, diminished their frequency, obtaining of the equation of time average among shortcomings, indexed to three months a value of: TMAF = 30240 [ℎ].

Carrying out a comparison with the time average of the previous methodology sees a substantial improvement, the time average among failure in the previous year’s Table 1. With the previous methodology it was of approximately of 7560 [ℎ] and now with the new methodology it is of 30240 [ℎ], very superior value [14-15].

Table 1. Comparison of the time failure average, in the last three years.

|

Years |

2020 |

2021 |

2022 |

|---|---|---|---|

|

Time average of failure |

7555 |

7855 |

7560 |

Source: [6].

This new methodology is not static as the previous one that its planning is conceived following a constant pattern of carrying out the maintenances once a year, in this, the administration of the maintenance and their planning is carried out from chord to the condition, the obtained data of the visual impactions, the application of technical of diagnostic, historical data of the maintenances and its operation, which can be implemented through the methods of Artificial Intelligence achieving a bigger efficiency in the administration of the maintenance [16-17].

He she has been able to check that the elements with bigge index of failure probability in a cell constitutes it the switch of half tension, the transformers of bony mensuration the transformer of currents and that of potential and the lightning rod. The switch in the devaluation of their contact resistance, which brings gets a deterioration of their means of extinction of the arch, in this case the gas hexafloruro of sulfur (SF6). For what is very important their operational control through the statistic and using the curve of waste of their contacts given by the makers, it should be considered that the waste of the contacts has an exponential behavior

The other elements like they are the mensuration transformers and the lightning rod game, their main cause of flaws is the potential jumps among the active part and its isolation product of the relative condensation of the humid one that he/she has a behavior average of 80 % during the year.

We exemplify in the table 2 of the maintenance plan made for the substation, the concerning action to the cell 1, in this case only the switch of half tension the one is exposed which presents deviation of their value norm of contact resistance detected by the applied actions of diagnoses, the control of their operational parameters, but in the same one the rest of the components is captured that conforms it.

Table 2. Maintenance action and I diagnose programmed.

|

Teams to maintain. |

That to verify. |

Rhythm of the intervention. |

|---|---|---|

|

Switch in Sf6 of 34,5 kV |

- Pressure of the gas to the nominal value, Quality of the Gas. -Resistance contact dynamics. -Infrared termografía. |

Once per week to carry out visual inspection and infrared termografía. Biannually cleaning and tests. |

|

Switch of 34,5 kV. |

-Resistance contac dynamics. -Infrared Termografía. |

Once per week to carry out visual inspection and infrared termografía. Once a year maintenance. |

|

Switch of earth. |

-Absence of corrosion in the contacts. -Adjust correct of the screws. -He/she witnesses of fat in the union. |

- Once a year maintenance. |

|

Current transformer of 34,5 kV. |

-Absence of corrosion in the borders of the unions.. -Adjust correct of the screws. - Infrared termografía. |

Once per week to carry out visual inspection and infrared. Biannually cleaning and tests. |

|

Potential transformer of 34,5 kV. |

- Absence of corrosionn -Adjust correct of the screws. - Infrared termografía. |

Once per week to carry out visual inspection and infrared termografía. Biannually cleaning and tests. |

|

Lightning rod of 34,5 kV. |

-Absence corrosion. - It proves of filtration current. -Infrared termografía. |

Eleven per week to carry out visual inspection and infrared termografía. Once a year cleaning and tests. |

Source: [6].

Conclusion

In the analysis that was carried out in the electric substation of the group electrógeno for the continuous mishaps taken place by jumps of currents in the elements that compose the electric cells, among the part you activate of the teams and earth that cause exits of service, with their inconveniences as they are lack of service to the client, repair of damaged elements that he brings gets expenses of material resources and of human capital and when not existing a procedure or methodology for the realization of the maintenances, the one is applied used in the substations of high tension of external in their majority of the cases, but the design of these substations conformed by cells inside an acclimatized local he has their specificities, besides not being carried out any type of diagnostic, it is necessary to establish a methodology for their conception,

For what is necessary to use as method of diagnostic the infrared termografía once per week, for which is had the necessary technical means as the infrared camera InfRec model R300R-D and this way to determine early the possible jumps of currents between the active part and earth.

References

[1] IEEE Std C37.10. IEEE Guide for Investigation, Analysis, and Reporting of Power Circuit Breaker Failures. United States of America: IEEE, 2011.

[2] CIGRÉ Working Group 13.06, “Final report of the second international enquiry on high voltage circuit-breaker failures and defects in service,” Int. Council Large Elect. Syst. (CIGRÉ), Paris, France, Tech. Brochure 83, 2010

[3] J. C. Casaña-Medel, I. Macías-Socarras, I. Morales-Tamayo, “El mantenimiento a partir de los indicadores de clases mundial en la fábrica Lácteos Bayamo” Revista Ciencias Técnicas Agropecuarias. 2021, vol. 30, n. 3, p. 115–132 ISSN 2071 – 0054. [Consultado el 25 de enero de 2022]. Disponible en: http://scielo.sld.cu

[4] B. Y. PEREA-LOZANO, H. N. LOPEZ SUAREZ, “Implementación de mantenimiento preventivo y predictivo en la empresa EQUIACERO SA” Revista UNILIBRE 2020, vol. 8, n. 3, p. 85–112

[5] J. J. MONTANÉ–GARCÍA, S.A. DORRBERCKER–DRAKE, O. N. HERNÁNDEZ–AREU, “El mantenimiento a los transformadores de potencia; su análisis en el caso de una central termoeléctrica cubana”. Ingeniería Energética Vol. XXXII, 2/2011 Abril – Julio p- 56- 64 ISSN 1815 – 5901.

[6] C. RUANO-GONZÁLEZ, “Metodología para el mantenimiento de interruptores empleados en las maniobras de reactores y bancos de reactores”. XIX Simposio de Ingeniería Eléctrica (SIE-2021). III Convención Científica Internacional 2021. Universidad Central de las Villas “Martha Abreu” Santa Clara. Noviembre 2021, ISBN:978-959-312-479-9.

[7] Revista Mantenimiento Mundial. “Indicadores de Clase Mundial”, vol. 3, núm 15[en línea]. [ref. de 16. de agosto 2019]. Disponible en Web: http://www.mantenimientomundial.com.

[8] A. VÉLEZ-QUIROZ, M. FILGUEIRAS- SAINZ DE ROZAS, M. VILARAGUT- LLANES, Revista Ingeniería Energética. 2022. Vol. 43, núm. 3, septiembre/diciembre. ISSN: 1815-5901.

[9] ABB. “Celdas Metal Clad-Metal Enclosed”. 2020.

[10] A. ROQUE-LOPEZ, “Transformadores Eléctricos”. Universidad Nacional Autonoma De Honduras. Tegucigalpa 2019.

[11] L. ZAPATA de la CRUZ, “Filosofía y generación de valores a través de la gestión de mantenimiento”, 20 Congreso Peruano Ingeniería de Mantenimiento, Lima. 2020.

[12] ITESA, soluciones de energía. “Celdas de Media Tensión: ¿Qué tipos hay?”, [en línea] 2022. Disponible en Web: http://www.itesa.com.pe

[13] R. Sánchez-Durán, “El futuro y el mantenimiento energético”. Universidad de Sevilla (España). Tesis Doctoral.https://dialnet.unirioja.es/servlet/tesis?codigo=283233, PP.234. 2020

[14] A. Moreno-Muñoz, Máster en Ingeniería del Mantenimiento (MUEA), “ Implementación del mantenimiento TPM, Técnicas Lean y 4.0”, Mayo 2022.

[15] C. DEUS- AGUILERA, J. CABRERA-GÓMEZ, Una mirada a la evolución natural del mantenimiento, Nota técnica 382, CubaMan, Diciembre de 2022.

[16] Fujitsu, Observatorio de Industria 4.0. España, El Mantenimiento Predictivo en la Industria 4.0, Club Excelencia en Gestión: www.clubexcelencia.org. 2022

[17] M. en C. M. Luna- Pérez., Doctorado en Ingeniería de Sistemas, Instituto Politécnico Nacional, SEPI ESIME Zacatenco, Diseño de una metodología de mantenimiento predictivo para asegurar procesos de producción de la industria 4.0, South Florida Journal of Development, Miami, v.2, n.1, p. 1009-1017, jan./feb. 2021. ISSN 2675-5459.

Declaración sobre uso de Inteligencia Artificial (IA)

El autor aquí firmante declara que no se utilizó ninguna herramienta de IA para la conceptualización, traducción o redacción de este artículo.

1 Departamento de ingeniería eléctrica. Facultad Electromecánica. Universidad de Camagüey. Cuba

cmruanog@gmail.com

cmruanog@gmail.com https://orcid.org/0000-0002-9647-8759

https://orcid.org/0000-0002-9647-8759