3. Results

3.1 Diagnosis of the circular economy level

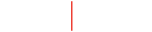

The checklist was then applied to identify the level of circular economy of the chain

under study. The value of the chain indicator was found to have a medium level with a metric of 2.69. Some of

the variables with the most flaws are the source or supply of materials (with a mean of 2.63), followed by

design (with a mean of 2.66), the economic circle (with a mean of 2.68), collection (with a mean of 2.69),

distribution and sales (with a mean of 2.72), manufacturing (with a mean of 2.83), and design (with a mean of

2.88).

The CEL for the agri-food chain was 2.69, which was evaluated as being a medium value. The

main descriptive statistics for this variable are shown in Table 1, which illustrates a

shift toward low performance by the actors in the chain. The standard deviation, minimum, and maximum values

show how different the versions were.

Table 1: Displays descriptive statistics for CEL variable.

| Statistic |

Mean |

Median |

Standard deviation |

Minimum |

Maximum |

| Value |

2.69 |

2.88 |

0.69 |

1.00 |

4.26 |

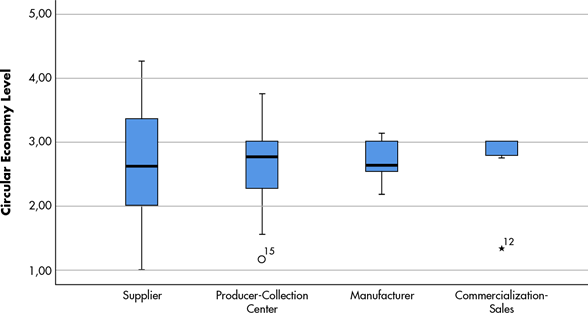

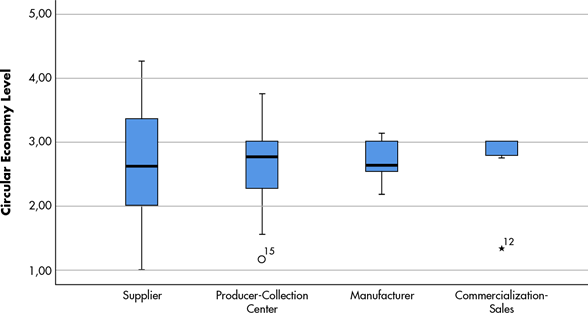

When the CEL variable was filtered by chain link, it was found that the links behaved

similarly in terms of mean values, with the Supplier link attaining the greatest diversity as regards the

performance of the actors owing to its high variability (Figure 2).

Figure 2: CEL variable filtered by chain link.

The Kruskal-Wallis non-parametric test yielded a sigma value of 0.887, which suggested

that there were no significant differences between the medians in terms of CEL (Table 2).

The similarity of ranks demonstrates this decision, corroborating the analyses performed using the box plots

above.

Table 2: Results of the Kruskal-Wallis Test.

| |

Link |

n |

Average rank |

Kruskal-Wallis test |

|

| CEL |

Supplier |

11 |

24.45 |

Kruskal-Wallis test H |

0.641 |

| |

Producer-Gathering Center |

20 |

22.00 |

gl |

3 |

| |

Transformer |

6 |

23.00 |

Asymptotic sig |

0.887 |

| |

Marketing-Sales |

9 |

26.00 |

|

|

The results of the hierarchical procedure in cluster formation are summarized in Table 3. It was deduced that combinations of various clustering methods with different

distance measures coincided in suggesting two and three clusters.

Table 3: Summary of the hierarchical procedure for cluster formation.

| Clustering Method |

Distance measure |

Number of clusters |

| Nearest neighbor |

Euclidean distance squared |

4 |

| |

Blocks |

5 |

| Nearest neighbor |

Euclidean distance squared |

2-3 |

| |

Blocks |

2-3 |

| Ward's linkage |

Euclidean distance squared |

2-3 |

| |

Blocks |

2-3 |

The non-hierarchical k-means procedure was then used to form two and three clusters (K=2

and K=3). The results for two sets indicated that convergence was reached quickly in the third iteration. The

number of players was 28 and 18 for clusters 1 and 2, respectively (Table 4). Cluster 1 was

determined to be composed of stakeholders with a superior performance when compared to those in Cluster 2,

with the exception of the sustainability dimension, which did not contribute to discriminating between these

two clusters.

Table 4: Summary of the hierarchical procedure for cluster formation.

| Iteration history |

|

|

Final centers of the clusters |

|

|

Actors by cluster |

|

| Iteration |

Change in cluster centers |

|

Variable |

Cluster Variable |

|

|

|

| |

1 |

2 |

|

1 |

2 |

1 |

2 |

| 1 |

3.137 |

3.308 |

Source of supply |

3 |

2 |

28 |

18 |

| 2 |

0.075 |

0.111 |

Design |

3 |

2 |

Total=46 actors |

|

| 3 |

0.000 |

0.000 |

Manufacturing |

3 |

2 |

|

|

| |

|

|

Economic circle |

3 |

2 |

|

|

| |

|

|

Distribution and sales |

3 |

2 |

|

|

| |

|

|

Consumption |

3 |

2 |

|

|

| |

|

|

Reuse |

3 |

2 |

|

|

| |

|

|

Remanufacturing |

3 |

2 |

|

|

| |

|

|

Sustainability |

3 |

3 |

|

|

The non-parametric Mann-Whitney U test revealed that the two clusters formed differ

significantly in terms of medians in all survey dimensions.

The results for three clusters indicated that convergence was reached quickly in the third

iteration (Table 5). Cluster 1, which was composed of low-performance actors, was identified

as having scores of between 1 and 2. Cluster 2, which contained medium-performance actors, obtained median

scores of 2 and 3. Cluster 3, which obtained scores of 3 in all dimensions, was consequently that which

performed best. All of the above was obtained for 5, 17, and 24 actors per cluster, respectively.

Table 5: Summary of the k-means procedure for three clusters (K=3)a.

| Iteration history |

|

|

|

Final centers of the clusters |

|

|

|

Actors by cluster |

|

|

| Iteration |

Change in cluster centers |

|

|

Variable |

Cluster variable |

|

|

|

|

|

| |

1 |

2 |

3 |

|

1 |

2 |

3 |

|

|

|

| 1 |

2.318 |

3.239 |

2.822 |

Source of supply |

1 |

2 |

3 |

5 |

17 |

24 |

| 2 |

0.518 |

0.214 |

0.073 |

Design |

1 |

3 |

3 |

Total=46 actors |

|

|

| 3 |

0.000 |

0.000 |

0.000 |

Manufacturing |

2 |

2 |

3 |

|

|

|

| |

|

|

|

Economic circle |

1 |

2 |

3 |

|

|

|

| |

|

|

|

Distribution and sales |

2 |

2 |

3 |

|

|

|

| |

|

|

|

Consumption |

2 |

2 |

3 |

|

|

|

| |

|

|

|

Reuse |

1 |

2 |

3 |

|

|

|

| |

|

|

|

Remanufacturing |

1 |

2 |

3 |

|

|

|

| |

|

|

|

Sustainability |

2 |

3 |

3 |

|

|

|

The non-parametric Mann-Whitney U test revealed that the three clusters formed differ

significantly in terms of medians in all survey dimensions.

The contingency table procedure was repeated for two and three clusters in order to

determine a relationship between the membership cluster variables and the chain-link variable. Table 6 showed that the clusters formed are not linked to the supply chain link variable.

Table 6: Contingency table procedure.

| Statistic |

K=2 |

|

|

K=3 |

|

|

| |

Value |

df |

Sig. Monte Carloa |

Value |

df |

Sig. Monte Carloa |

| Pearson's chi-square |

3.738 |

3 |

0.315 |

2.545 |

6 |

0.886 |

| Likelihood Ratio |

4.298 |

3 |

0.263 |

3.140 |

6 |

0.791 |

The above results are equivalent to each other and allow us to conclude that the

performance of the actors in terms of CEL does not depend on the link in the chain in which the actor is

located. Hence, the strategy to be designed will be general for the entire chain, but not specific by each

link.

3.2 Predicting the circular economy

Two prospective techniques were used in order to predict the level of the economy that the

chain being studied would have: SVM and NN. The former identified the input variables (the nine variables) and

output variables (CEL). It took 70% of the data to test the model, and another 30% of the data to validate it.

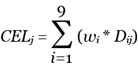

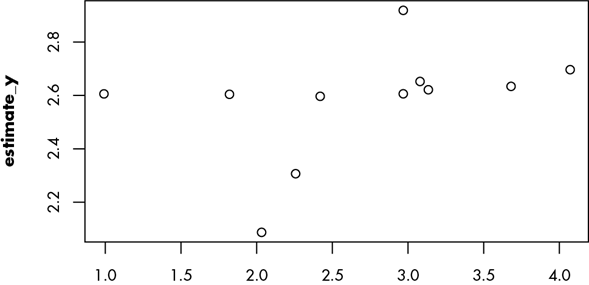

SVM Regression Radial Kernel: The execution time of the SVM learning algorithm was 3

seconds. This demonstrated the performance of the second with regard to time. The estimated results of the

resulting variable indicated that the vector model would perform better estimates of the input variables in

the initial layer. In order to evaluate the SVM model, 30% of the data, which was not part of the machine

training, was used. This model was then employed to estimate the values using the process described above. The

Spearman correlation coefficient was calculated to ensure that the data were as similar and as close as

possible. These estimators were then compared to the real values. With regard to the correlation, the chain

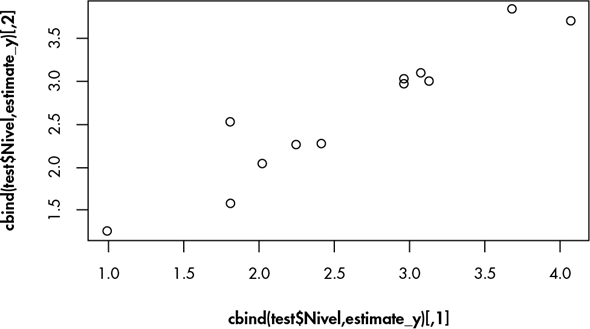

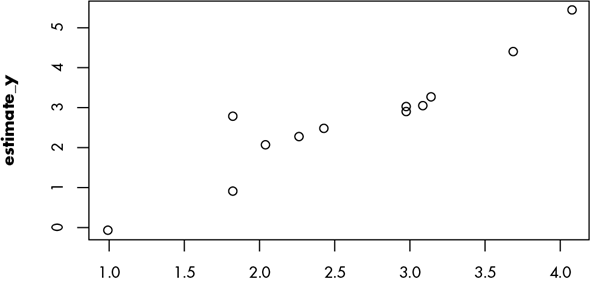

results were 0.405, which is low (Figure 3).

Figure 3: The regression coefficient of the SVM-Radial Kernel model.

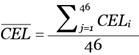

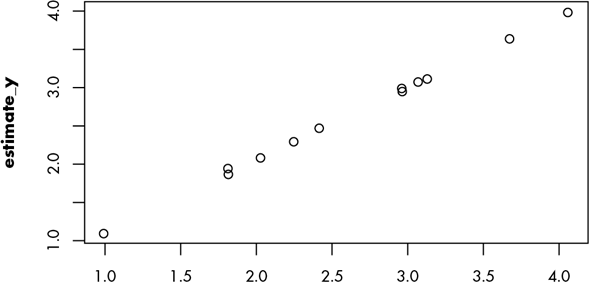

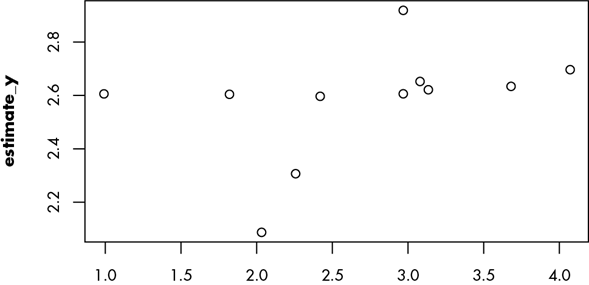

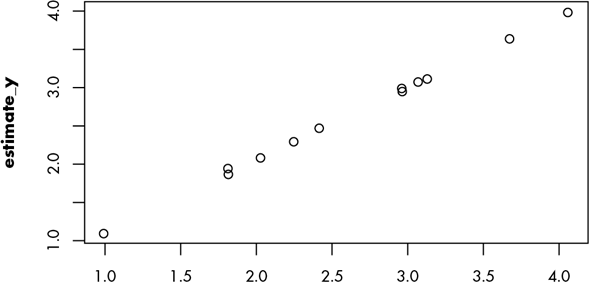

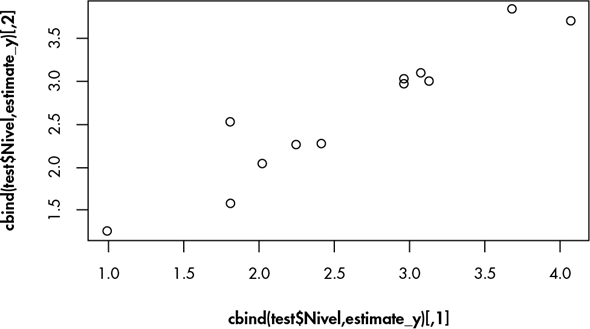

SVM regression - Linear Kernel: The application conditions of the technique were similar.

With regard to the correlation of the SVM-Linear Kernel model, the result of the chain was 0.999, which is

high (Figure 4).

Figure 4: The regression coefficient of the SVM-Linear Kernel model.

SVM Regression Polynomial Kernel: The application conditions of the technique were

similar. With regard to the correlation of the SVM for the Regression-Polynomial Kernel model, the chain

result was 0.931, which is high (Figure 5).

Figure 5: The regression coefficient of the SVM model for regression-Kernel polynomial.

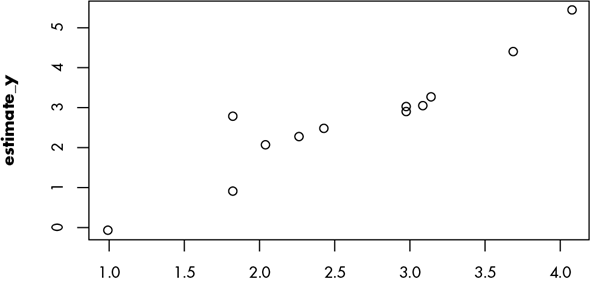

The data in which each of the variables is passed to each input neuron is known as the

output. This calculation was performed for each NN neuron. The real and estimated values corresponded to 30%

of the data used to test the model. There were some negative estimators, which were preliminary results, and

the ranges had to be adjusted. With regard to the correlation of the NN model for regression, the chain

results were 0.953, which is high (Figure 6).

Figure 6: The correlation coefficient of the NN model.

These four estimation tools were applied, which made it possible to obtain Spearman's

correlation coefficients (ρ) (Table 7).

Table 7: Results of the correlation coefficients of the methods.

| Methods applied |

ρ |

| SVM Radial Kernel |

0.405 |

| SVM Linear Kernel |

0.999 |

| SVM Polynomial kernel |

0.931 |

| NN |

0.953 |

Of the four estimation tools, three are robust, as stated by Muñoz et al.

(2020) , because they have a value higher than 0.90. However, the strongest is the SVM for the

regression-Linear Kernel, which has a coefficient closer to 1, which is the highest of all. This implies that

the most reliable predictions are related to this model.

3.3 A comparative analysis of the application of the circular economy to other

production chains

Table 8 shows the analysis of the evaluation results of the CE when compared with other

cases of the application of the tool to agri-food chains. These studies focus on other sectors in Ecuador and

Mexico, such as the conventional cocoa (Diéguez-Santana et al., 2021), the organic cocoa

chain (Bravo-Mendoza et al., 2020), the coconut chain in Ecuador (Camacho-Vallejo et al., 2022) and the pitahaya chain, which was recently studied in the

Amazon, Ecuador (Diéguez-Santana et al., 2022). The overall results (total of the nine

indicators) presented in this production chain (2.69) are higher than those of the organic cocoa and coconut

chains in the province of Manabí, and than the evaluation of the pitahaya chain in the Amazon, Ecuador,

although lower than the evaluation carried out for the cocoa chain in Mexico, which recorded a value of 2.98.

The values for each indicator are slightly higher than those for the chains above, which

have lower values. However, the sustainability indicator is higher for the cocoa in the Mexican and Ecuadorian

chains. The source or supply (2.63) and re-manufacturing (2.93) indicators are also higher than in previous

studies. However, these are still low values, with no indicator scoring 3 out of 5 points. Furthermore, the

design criterion is exceeded in the Manabí cocoa chain (2.69 vs. 2.66). With regard to distribution and sales,

the cocoa chains (Manabí and Mexico) exceed the indicator results (3.23 and 2.98 vs. 2.72 points).

Although some indicators have attained better results than in other studies, there are

many difficulties in the activity that must be analyzed in order to improve income and environmental

sustainability. Some strategies with which to boost the CE in banana crops in the province are presented in

the following section.

Table 8: Comparison of the results of this study with other cases in which the CE in agri-food chains

was evaluated.

| No |

Criteria |

Conventional cocoa chain, Mexico |

Organic cocoa, Manabí, Ecuador |

Coconut chain, Manabí |

Pitahaya, Ecuador |

Banana, Manabí |

| Reference |

|

(Diéguez Santana,

Rodríguez Rudi, et al., 2021) |

(Bravo Mendoza et al.,

2020) |

(Camacho-Vallejo et al.,

2022) |

(Diéguez Santana et

al., 2022) |

This work |

| 1 |

Source of supply |

2.54 |

2.06 |

1.09 |

1.72 |

2.63 |

| 2 |

Design |

2.25 |

2.69 |

1.4 |

1.93 |

2.66 |

| 3 |

Manufacturing |

2.8 |

1.3 |

1.81 |

2.6 |

2.83 |

| 4 |

Economic circle |

3.5 |

2 |

2.39 |

2.45 |

2.68 |

| 5 |

Distribution and sales |

3.23 |

2.98 |

1.39 |

1.75 |

2.72 |

| 6 |

Consumption |

3.22 |

1.19 |

1.46 |

2.2 |

2.69 |

| 7 |

Reuse |

2.94 |

1.64 |

1.3 |

2.1 |

2.88 |

| 8 |

Remanufacturing |

2.8 |

1 |

1.01 |

1.75 |

2.93 |

| 9 |

Sustainability |

3.5 |

4.03 |

2.21 |

2.75 |

2.94 |

| - |

Total (9 indicators) |

2.98 |

2.1 |

1.56 |

2.14 |

2.69 |

3.4 Prospective for improving CE in Ecuador's banana production chain

The difficulties encountered in the evaluation of the CE make it necessary to address

strategies with which to improve the production chain of the banana sector in Ecuador. It is necessary to

transform the waste and by-products of the process into value-added products, and options by which to increase

the value of waste could, therefore, be strategies to consider with the CE approach. This includes the

application of emerging technologies since, as argued by Negroiu et al. (2021) , increasing

the value of residues through the use of technologies does not lead to the destruction of nutrients or other

valuable components and they can, therefore, transformed into value-added products, thus minimizing losses by

converting them into resources.

In the case of bananas, the entire production process, from the agricultural stage to

processing, leaves fractions of unused waste. For example, in the processing plants where bananas are sorted

and packed, fruit that has not reached an optimal state of maturity and adequate size, or has slight bumps or

bruises, insect bites, and stains, is discarded and added to the losses of the harvesting process (Bhushan et al., 2019). Other significant fractions in the banana industry include waste,

including the loss of roots, stems, leaves, or any other part of the plant that is not used during processing.

These are made up of lignin, cellulose, pectin, and hemicellulose (Velasteguí et al.,

2017). Table 9 shows the chemical composition of the main residues derived from the

process.

Table 9: Chemical composition of banana processing wastes.

All these fractions generated in the banana industry contain essential nutrients for

incorporation into value augmentation processes. Some of them range from biofuels, organic fertilizers,

biomaterials for wastewater treatment, and bioplastics, including the production and application of

nanomaterials, which can be implemented using a circular economy approach. Table 10 shows

the main recovery processes that can be applied to each type of waste from the banana industry.

Table 10: Recovery processes applied to banana industry waste.

| Type of waste |

Type of product |

Scale of study |

Relevant results |

Reference |

| Organic fertilizers |

|

|

|

|

| Pine sawdust and mango peel and Musa

spp. |

Bokashi |

Pilot |

Waste in piles (1:1:1 ratio) were

turned daily for the first ten days to maintain the temperature of 70 °C. The decomposition process

lasted 21 days. Bokashi had an electrical conductivity of 8.97 mhos/cm, potassium content of 4.3 mg/kg

bokashi and sodium content of 161.0 mg/kg |

(Mendivil-Lugo et al.,

2020) |

| Fruit peel, Pseudostem and leaves of

Musa Paradisiaca |

Vermicomposting |

Industrial |

The earthworm Eudrilus eugeniae

was introduced into the shredded waste. The best result as regards the chemical composition of the

prepared vermicompost was N-17.21% , P-10.24%, K-48.32% and a C/N ratio of 29. |

(Mahmud et al.,

2019) |

| Municipal waste, peel, and pulp of Musa

spp. |

Compost |

Pilot |

Microorganisms were inoculated with

cow dung and 2 cm waste in 170 L containers with 50 kg of solid waste. The final product had nutrient

values of N-2.13%, P-0.57%, K-7.68%, Ca-16,000 mg/kg, Mg-14,600 mg/kg, Fe-113 mg/kg, Cu-89 mg/kg and

Zn-154 mg/kg. |

(Devi &

Mugilvannan, 2018) |

| Municipal waste, peel and pulp of Musa

spp. |

Black soldier fly composting |

Pilot |

Pretreatment of banana peel with

Hermetia illucens. The peel was homogenized and mixed with ethanol, methanol, chloroform, and

nitrogen. The mixture containing nitrogen produced the highest final larval weight (134 mg). |

(Isibika et al.,

2019) |

| Biofuel |

|

|

|

|

|

Banano Cavendish rachis and peel

|

Bioethanol |

Laboratory |

Banana peel and rachis subjected to an

alkaline hydrolysis process with NaOH were fermented. The ethanol obtained had an average pH of 4.16

and a Brix of 3.75, with a concentration of 29 degrees alcohol and a distillate flow rate of 8.3 mL/s.

|

(Adrianzen-Fiestas,

2018) |

|

Musa acuminata pseudostem, rachis.

|

Biogas |

Laboratory |

An anaerobic bioreactor was fed with

ripe banana peel. After 8 h, 1 L of gas was obtained in the sampling system. (CO2

concentration of 99.97%). |

(Romero et al.,

2017) |

| |

|

Pilot plant |

Residues (pseudostem and rachis)

underwent anaerobic digestion followed by steam explosion pretreatment. A yield of 363.29 L of

CH4 /kg of residue was obtained. |

(Durán-Hernández,

2020) |

| CáscaradeplátanoytallodeMusaspp

|

Biodiesel |

Laboratory |

Cryptococcus sp. was grown on pretreated banana peel, and its lipid accumulated up to 34.0%.

The lipid had a high degree of monounsaturation, which gave the resulting biodiesel better quality

|

(Han et al., 2019)

|

|

Musa paradisiaca Peel

|

Hydrogen |

Laboratory |

Banana peel and brewery wastewater in

a batch bioreactor. The maximum hydrogen production yield (408.33 mL H2 /L wastewater) was

achieved from the substrate, consisting of 50% of the weight pretreated with 1 g/L plantain peel for

two hours and 50% medium standard. |

(Al-Mohammedawi et al.,

2019) |

| Cavendish peel |

Biochar |

Laboratory |

Slow pyrolysis (T=356.1 °C and heating

rate of 14.7 °C/min). The biochar yield was 58.8 % (O/C ratio 0.289). |

(Te et al., 2020)

|

| Biomaterials for wastewater treatment

|

|

|

|

|

|

Musa Acuminata peel

|

Coagulant |

Laboratory |

The dried husks were soaked with

distilled water and agitated at 120 rpm for one hour. The coagulant was highly effective at removing

turbidity from synthetic wastewater, with a removal efficiency of 88% at pH 1.0 conditions and a

dosage of 100 mg/L. |

(Mokhtar et al.,

2019) |

|

Musa AAB Pseudo stem

|

Biofilters |

Laboratory |

The biofilter was made from cellulose

and holocellulose extracted from pseudo stem. The biofilter was able to remove organic contaminants

with an efficiency of between 70.4 and 84.2%. |

(Zaman et al.,

2020) |

|

Musa paradisiaca rachis

|

Activated carbon |

Laboratory |

Charcoal from banana rachis had a

chromium removal efficiency of 99.8% at pH 6.7. In addition, the biological oxygen, biochemical,

chemical oxygen demand, and chloride reduction efficiencies were 97%, 93% and 60%, respectively. |

(Payel et al.,

2018) |

|

Musa spp peel

|

Biosorbent |

Laboratory |

The husk was ground to a particle size

of 2 mm and dried. An oil removal efficiency of over 96% was achieved from the wastewater. |

(Okologume &

Olayiwola, 2019) |

|

Musaspp peel

|

Ceramic membrane |

Industrial plant |

The husk was ground, mixed in a mold

subjected to 88 MPa and screened at 150 µm. Tanning contaminants, turbidity, dye content, suspended

solids, and BOD were reduced. |

(Mouiya et al.,

2019) |

|

MusaSapientunPseudo stem

|

Biosorption |

Laboratory |

Dried pseudo stems achieved removals

of oxygen demand of 88%, ammonia nitrogen 84%, suspended solids 83%, turbidity 75%, color 67%, and oil

and grease 68%. |

(Daud et al., 2017)

|

| Bioplastics |

|

|

|

|

|

Musa spp Pseudo stem

|

Cellulose/ biodegradable film |

Laboratory |

Cellulose film decomposed in soil in

four weeks, indicating excellent biodegradability when compared to polystyrene (PE) plastic films.

|

(Ai et al., 2021)

|

|

Musa Paradisiaca peel

|

Starch/ biodegradable planting bag

|

Laboratory |

The biodegradable plastic degraded

quite rapidly, with an average percentage weight loss of 65.1 % in eight weeks. |

(Huzaisham & Marsi,

2020) |

|

Musa Paradisiaca peel

|

Starch/ Polyhydroxyalkanoate (PHA)

|

Laboratory |

Banana starch was added to potential

PHA producers. Geobacillusstearothermophilus accumulated 84.63% PHA in 96 h. Bacillus

subtilis accumulated 71.78% PHA in 24 h of incubation. Bacillus siamensis accumulated

77.55% and Staphylococcus aureus had about 70.02% PHA in 24 h of incubation. |

(Rayasam & Kumar,

2018) |

|

Musa Paradisiaca peel

|

Starch/ Bioplastic |

Laboratory |

The bioplastic film can support a

weight of close to 2 kg with sufficient traction and strength. The fabricated bioplastic can be used

as a packaging material or for transportation. |

(Chandarana &

Chandra, 2021) |

| Production and application of

nanomaterials |

|

|

|

|

|

Musa balbisiana Leaves

|

Silver nanoparticles/ Microwave

assisted biosynthesis |

Laboratory |

The particle size was 80 to 100 nm and

was crystalline. The nanoparticles were effectively used in anticancer study activities. |

(Mohammadlou et al.,

2016) |

|

Musa balbisiana Leaves

|

Silver nanoparticles/ Green Synthesis

|

Laboratory |

Silver nanoparticles synthesized by

the green method exhibited an absorption maximum of 410 nm. Nanoparticle micrographs indicated

spherical silver nanoparticles with a size range of 20 to 300 nm. |

(Khan et al., 2019)

|

|

Musa spp. shells and pseudostems

|

Nanosilica/composite polymer |

Laboratory |

Banana fibers (5 wt.%) with 0.1 wt.%

nanosilica fillers were used. The polymer had a density of between 0.8 and 1.5 g/cm3 and a

hardness of 50 to 92 on the Rockwell scale. |

(Rahul et al.,

2017) |

As can be seen, the conventional processes in Table 10 show that

different types of organic fertilizers can be implemented, such as Bokashi, Vermicomposting (which can include

various types of worms), conventional composting processes, or the use of the Black Soldier Fly. The high

content of carbohydrates and cellulose in some fractions facilitates the occurrence of these processes,

coupled with the availability of waste that is sometimes high. Another application is focused on the

production of biofuels. These include biochemical (alcoholic fermentation, anaerobic digestion), chemical

(transesterification), or thermochemical (gasification, pyrolysis) routes, the main products being bioethanol,

biogas, and biodiesel, hydrogen, and coal, among others. With regard to their use as biomaterials for

wastewater treatment, as shown in Table 10, the main benefits include coagulants

(coagulation-flocculation), filter beds (biofilters), and adsorption/biosorption (activated carbons,

biosorbents), or systems with membrane separations (ceramic membrane). This shows the diversity of

applications in this context that could be implemented in order to increase the value of the waste produced by

this agri-food chain.

Furthermore, the high content of organic compounds that are rich in carbon

(polysaccharides) allows fractions such as banana peel to be used to obtain bioplastics. Similarly, the

fibrous composition of banana pseudo stem reduces the biodegradation time required for the processes employed

to obtain bioplastics. Moreover, the leaves of the plant have been used to produce biodegradable packaging and

utensils. The composition of these process fractions (leaves, rachis, pseudo stems, and banana peel) has

recently attracted the attention of those interested in nanotechnological processes, mainly in the production

of green nanoparticles (e.g., the biosynthesis of silver nanoparticles). As shown, banana residues have a high

potential for utilization and can be sources of raw materials to be reused in various value-increasing

processes. In addition, it closes production cycles and reduces the amount of banana industry waste that

builds up, because it can be used in many different ways, which helps the circular economy grow.