Article

DOI:

https://doi.org/10.18845/te.v16i3.6367

Innovation capabilities and export performance in manufacturing SMEs

Capacidades de innovación y desempeño exportador en las Pymes manufactureras

TEC Empresarial, Vol. 16, n°. 3, (September - December, 2022), Pag. 55 - 71, ISSN: 1659-3359

AUTHORS

Joaquín Alegre*

afiliación

joaquin.alegre@uv.es.

![]()

José Luis Ferreras-Méndez

University of Valencia, Spain

j.luis.ferreras@uv.es.

![]()

Anabel Fernández-Mesa

University of Valencia, Spain.

anabel.fernandez@uv.es.

![]()

Roger Strange

University of Sussex, United Kingdom of Great Britain and Northern Ireland.

R.N.Strange@sussex.ac.uk.

![]()

Corresponding Author: Joaquín Alegre

ABSTRACT

Abstract

Export performance has become an increasingly important issue for SMEs in recent years as a result of the widespread phenomenon of globalization and the economic recession in some regions. Innovation has been proved to play a determinant role in export performance. In this paper, we propose a new comprehensive conceptualisation of innovation capabilities for manufacturing firms that includes capabilities in three key areas for innovation activities: technology, marketing and design. Using a database on Spanish manufacturing SMEs, we check the validity and reliability of this new innovation capabilities conceptualisation and then we test its effect on export performance. We find that those firms that are proficient in technology, marketing and design show higher levels of export performance. These findings are important for the innovation and internationalisation literature as well as for SME managers: emphasising technology, marketing and design contributes to facilitating SMEs’ performance in the international arena.

Keywords: Innovation Capabilities Technology; Marketing; Design; Export Performance.

Resumen

El desempeño exportador representa una cuestión cada vez más importante para las PYMEs como resultado del fenómeno de la globalización y de la recesión económica en algunas regiones. La innovación juega un papel determinante en la promoción de las exportaciones. Este trabajo propone una nueva conceptuación de tipo formativo de las capacidades de innovación para las PYMEs manufactureras que incluye capacidades en tres áreas clave: la tecnología, el marketing y el diseño. Usando una base de datos de PYMES manufactureras españolas, comprobamos la validez y la fiabilidad de esta nueva conceptuación de las capacidades de innovación. También verificamos en efecto positivo de estas capacidades sobre el desempeño exportador. El trabajo señala que las PYMEs que dominan al menos alguna de esas tres capacidades de innovación obtienen niveles más elevados de desempeño exportador. Estos hallazgos son importantes para la literatura en innovación y en internacionalización. La recomendación para las personas que tomas decisiones estratégicas en las PYMEs es que vale la pena enfatizar esfuerzos en el dominio de la tecnología, el marketing y/o el diseño ya que esto facilita su desempeño en el contexto internacional.

Palabras clave: Capacidades de innovación; Tecnología; Marketing; Diseño; Desempeño exportador.

Introduction

1. Introduction

Innovating and exporting play a vital role in the strategies of Small and Medium Enterprises (SMEs) (Kafouros et al., 2008; Golovko and Valentini, 2011; Leonidou et al., 2015; Battaglia and Neirotti, 2020). Both, innovation and exports have very much to do with creativity, renewal and openness to the environment (Chiva et al., 2014). Exporting allows SMEs to sell their products in foreign markets and, as a result, benefit from economies of scale. This is especially important in the case of SMEs in countries that experience demand contraction due to the economic crisis. Exporting SMEs in countries in economic recession are in a better position to deal with reductions in domestic sales. Their export turnover leads to an increase in their general turnover and, most importantly, it provides them with liquidity, one of the most problematic issues for SMEs in regions that are in recession (Fernández-Mesa and Alegre, 2015; Ausloos et al., 2018). Moreover, exporting might be achieved with a less resource-laden approach as compared with alternative foreign market entry modes (Morgan et al., 2012). As a result, exports greatly affect SMEs overall performance (Stoian at al., 2011; Stoian et al., 2017).

Innovation consists of successfully implementing creative ideas within an organisation (OECD, 2018). The importance of product innovation for good long-term company results is now widely recognised and has been extensively reported in the literature (Capon et al., 1992; Dolfsma and van der Eijk, 2017; Hervás-Oliver et al., 2018).

Following the Resource-Based View (RBV) of the firm, our first objective is to propose a new and comprehensive conceptualisation of innovation capabilities for product development that fits especially the context of manufacturing SMEs. This new approach consists of the aggregation of three widely accepted capabilities: technology capabilities, marketing capabilities and design capabilities. While previous literature has successfully combined technology and marketing capabilities (Schmookler, 1966; OECD, 2018; Tidd and Bessant, 2018), the inclusion of design capabilities represents a new approach to consider innovation capabilities.

Some SMEs do very well in terms of innovating and exporting in the context of globalised and science-based industries (Pla-Barber and Alegre, 2007). However, because of their size and their endowment of resources, it is normally difficult for SMEs to be in the technological avant-garde in manufacturing industries. Similarly, due to their limited production and distribution capacity, manufacturing SMEs tend to focus on small market niches although they might show a very exporting behaviour (Oura et al., 2016; Cerrato et al., 2016). Finally, it is important to highlight that some manufacturing SMEs pay special attention to design management and design outcomes. Although design management has been an under-studied organisational process (Chiva and Alegre, 2009; Magistretti et al., 2020), design allows SMEs to add a substantial amount of value to their products at a reasonable cost (Chiva and Alegre, 2009, Ravasi and Stigliani, 2012; Stigliani and Ravasi, 2018), especially in comparison with the costs of mastering particular technology or a specific market. For these reasons, we argue that including design capabilities as a dimension of innovation capabilities might provide a more realistic and balanced view on how manufacturing SMEs innovate and operate in the international arena.

Innovation and exports have been found to have a narrow and positive connection (Rogers 2004; Monreal-Pérez et al., 2012; Filipescu et al., 2013). Previous studies support a positive relationship both from the innovation and technology management perspective as well as from the international business point of view. On the one hand, innovation confers market power and thereby facilitates export activities (Roper & Love, 2002). Moreover, innovative firms will have a propensity to enter foreign markets in order to increase sales volume and spread the fixed costs of innovation over a larger number of units (Wakelin, 1998; Nassimbeni, 2001; Rogers, 2004; Tidd and Bessant, 2018). On the other hand, because exporting firms have specific and valuable knowledge on international markets, they are in an advantageous position to develop products and services that fit with foreign markets needs and wants (Kafouros et al., 2008; Leonidou et al., 2015).

SMEs’ success is dependent on a better understanding on how this connection works (Sousa et al., 2008). As a result, our second objective is to examine the relationship between our proposed innovation capabilities framework including technology, marketing and design with export performance in the context of manufacturing SMEs.

This paper is structured as follows. The next section sets out a conceptual framework for innovation capabilities and a theoretical review on the connection between innovation capabilities and export performance. In line with this theoretical review, a number of research hypotheses are put forward in the context of SMEs. In the following section, we explain our methods. We then describe the design of the survey, addressed to manufacturing Spanish SMEs, as well as the measures and the analyses used in this study. Finally, the results and conclusions are presented in the last two sections of the paper.

Hypotheses

2. Conceptual background and hypotheses

The resource-based view of the firm (RBV) is an influential theoretical framework for understanding value creation as well as differences within competitors in terms of performance (Zott, 2003). This perspective assumes that firms can regarded as distinctive sets of resources over time (Easterby-Smith et al., 2009; Villar et al., 2014). It has been theorised that the specific use of valuable and rare resources constitutes the foundation of competitive advantage, in both domestic (Yeoh and Roth, 1999) and international markets (Fahy, 2002; López-Rodríguez and García-Rodríguez, 2005). The innovation capabilities of a firm might be considered as relevant resources to achieve competitive advantage in exporting activities (Oura et al., 2016).

Previous studies have normally focused on innovation capabilities from the technology or from the market perspective (Hult et al., 2004; Camisón and Villar-López, 2012) or have successfully combined technology and marketing capabilities (Schmookler, 1966; OECD, 2018; Zang and Li, 2017). However, these previous studies could be disregarding design capabilities. Design is an important process that facilitates successful product innovation (Ravasi and Stigliani, 2012; Fernández-Mesa et al., 2013). As a result, the inclusion of design capabilities represents a new and more comprehensive approach to look at innovation capabilities.

Most innovation models acknowledge the role of technology and marketing for innovation (OECD, 2018; Zang and Li, 2017). Technology capabilities focus in providing new technical solutions for users’ problems (Di Benedetto et al., 2008). Technology capability can be defined through five distinctive abilities that enable firms to employ and develop various technologies: (1) coordination, (2) core technology, (3) innovation orientation, (4) commitment to R&D, and (5) autonomy of R&D decision (Huang, 2011).

Marketing capabilities allow the firm to update and understand users’ needs as well as to identify new users’ segments (Day, 1994; Song et al., 2005). Thanks to marketing capabilities, organisations can predict and adapt customer changes by building and sustaining relationships with customers and channel members. Marketing capability has to do with the coordination of marketing actions focusing resource deployments to achieve product-market goals (Vorhies et al., 2009).

Finally, design can be understood as the conception and planning of man-made objects (Bruce and Bessant, 2002). Design refers to as a set of choices regarding both the form and the function of an object, as well as the activities that underpin these choices. From this perspective, design is thus considered not only in terms of the final outcome, but also in terms of the process leading to that outcome (Ravasi and Stigliani, 2012). Design capability can be defined through five distinctive abilities: (1) basic design, (2) specialised design, (3) involving others, (4) organisational change, and (5) innovation (Dickson et al., 1995; Chiva and Alegre, 2009).

We argue that innovative firms create new products by focusing on technology, marketing and/or design. This is especially important for SMEs, since design is usually a more affor-dable activity than R&D to develop new technologies or market research and analysis (Ravasi and Lojacono, 2005; Chiva and Alegre, 2009). For these reasons, we put forward that a comprehensive innovation capabilities framework should include three different main capabilities: technological capabilities, marketing capabilities and design capabilities. We also propose that these innovation capabilities are to be considered as a formative model allowing firms to have different levels of excellence in these three capabilities: a firm could excel in all three capabilities or another firm could excel only in one of them. In order to test this proposal, we hypothesise the following:

Hypothesis 1: Innovation capabilities can be conceptualised as a formative second-order factor including technological capabilities, marketing capabilities and design capabilities.

Next, because of the relevance of exports for SMEs, we look at the relationship between innovation capabilities and export performance. The three innovation capabilities we are examining have been previously considered, in a separated way. as relevant resources to achieve excellent export performance and competitive advantage. This is especially the case for technology and marketing management (Yeoh and Roth, 1999; López-Rodríguez and García-Rodríguez, 2005; Chiva and Alegre, 2009; Oura et al., 2016). However, more empirical support is required for the understudied connection between design management and exports (Ravasi and Stigliani, 2012).

Further still, previous research has been rather fragmented when considering the connections between technology management, marketing management and design management. Although, in general terms, we could expect a positive connection among them because firms that aim at innovation tend to encourage all the processes involved with developing new products and services (Yeoh and Roth, 1999; Ardito et al., 2015), the scarce resource endowment of SMEs could also justify situations in which a particular SME does not have enough means to excel in the three innovation capabilities at the same time. This is the reason why we adopt a formative approach including these capabilities (technology, marketing and design) to examine the interplay between them and export performance. By doing so, we aim at providing a new and more comprehensive picture on the link between innovation and exports that emphasises the specific role of each of the following capabilities: technological capabilities, marketing capabilities and design capabilities. Because of the formative approach we adopt for innovation capabilities, we can scrutinise the importance of each capability for a particular firm (Hair et al., 1998; Diamantopoulos and Siguaw, 2006). Hence, we assume that some firms could excel simultaneously in the three innovation capabilities while others could be excellent only in one of them and still do well in the international arena.

This new approach allows us to better understand the innovation options of manufacturing SMEs in terms of technology, marketing and design as well as their specific impact over a crucial internationalisation performance indicator for SMEs such as exports. We argue that this new perspective might be helpful to better understand the antecedents of manufacturing SMEs success.

Thus, we put forward the following hypothesis:

Hypothesis 2: Innovation capabilities have a positive effect on manufacturing SMEs export performance.

Methods

3. Methods

3.1 Sample and Data Collection

A survey over manufacturing SMEs was undertaken to collect primary data. Field work was carried out from December 2011 to middle March 2012. We focused on three important manufacturing industries in Spain that are organised as SMEs networks: ceramics, toys and footwear. A total of 1217 manufacturing SMEs were identified through sectorial directories in ceramics, toys and footwear industries. A pre-test was carried out on four experts for each industry to assure that the questionnaire items were fully understandable in the context of these industries. These experts were recruited among company managers and technological institutes technicians. In order to avoid common method variance bias, the questionnaire was addressed to two company directors on a face-to-face interview. Questions related with innovation capability were answered by the product development manager or equivalent, while questions related with export were answered by the sales manager or equivalent. Splitting the questionnaire into two sections (innovation capabilities and export performance) had the additional advantage of reducing the time required for answering the questions.

Finally, we received a total of 347 completed questionnaires. Our final database is made out of by 105 firms from ceramic industry, 144 from shoe industry and 98 from toy industry. Our sample represents 28.51% of the total target population. Both, the number of responses and the response rate can be considered satisfactory (Spector, 1992; Williams et al., 2004).

3.2 Measures

Innovation capabilities is conceived as a second-order factor including three different dimensions (see appendix): technology capability (Huang, 2011), marketing capability (Vorhies et al., 2009) and design capability (Dickson et al., 1995). The original measurement scales from Huang (2011) and Dickson et al., (1995) are very comprehensive and combine issues that go beyond the core of the concept. For example, Huang (2011)’s technology capability measurement scale includes a coordination capability or a competitive environment assessment. Dickson et al., (1995) incorporate leadership in their design management.

For this reason, technology capability is measured with the dimension of “core technology capability” from the scale of technology capability from Huang (2011)’s study (see Appendix). This scale measures the extent of core technology developed by firms in comparison to their competitors.

Market capability is measured with the marketing architectural capabilities from Vorhies et al., (2009)’s study. This scale measures the degree to which firms engage in specified routine marketing activities. As a result, it measures how well the respondent performed the marketing activities relative to their closest competitors (Day, 1994; Grant, 1991). It is composed by 4 items: (1) environmental scanning, (2) market planning, (3) marketing skill development and (4) internal coordination and communication.

Finally, design capability is measured through the basic design capabilities dimension from Dickson et al., (1995)’s study. Respondents had to indicate whether each of these new product design issues is one your firm manages well or whether it is one your firm has trouble managing.

Regarding the dependent variable, export performance is measured with the scale used by Lages et al., (2009) . All measurement scales are available in the Appendix. Each measure scale was applied using 8-point Likert scale, where 1 represents total disagreement and 8, total agreement.

As control variables, size, industry, exports intensity and environmental turbulence were included. Previous studies have found significant relationships between size, industry and export variables (Cassiman and Veugelers, 2006). To capture the industry, we introduced dummies variables. The variables of industries are dummies (dichotomic) what means that the value is one if the company is from this industry or 0 if it is from other. In the sample three industries were included: ceramic, footwear and toy, however only the dummies of two of the industries are displayed in the model as the software uses the third one as refence for estimating the model. Environment turbulence was measured with two items which capture how the technology and customers’ needs change in the market where firms operate. Finally, export intensity was measured as the percentage in sales that correspond to exports.

3.3 Results

Assessing Formative Measurement Models

According to Bollen (1989) , traditional validity assessments and classical test theory do not apply to manifest variables that are used in formative measurement models. Therefore, concepts of reliability (i.e convergent and discriminant validity) are not meaningful when a formative model is employed (Henseler et al., 2009). It is recommended two kinds of assessment to secure validity of formative measurement: theoretic rationale and statistical analyses at two levels, construct and indicator level (Henseler et al., 2009, p. 301).

To evaluate the formative measurement at the construct level it is necessary to check the nomological validity. The above help to see to what level the formative index behaves within a net of hypotheses as expected. Moreover, it is necessary to consider the construct error term v, which represents the part of the construct that is not captured by any indicator. To estimate the size of this error, it is necessary to regress the formative index on a reflective measure of the same construct. The external validity can finally be calculated as 1 - Var (v). The current literature does not provide any recommendations for thresholds of external validity, but it is recommended a minimum value of 0.8 for external validity (Henseler et al., 2009). The above would mean that the formative index carries about 80% of the intended meaning.

The results obtained for this index ensure the external validity of the formative construct.

Var (v) = 0

External validity = 1 - 0 = 1

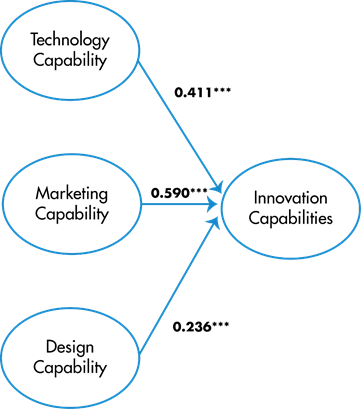

At the indicator level it is necessary to analyse the important relevance of the construct for the construction of the formative index and the level of multicollinearity that may exist (Henseler et al., 2009). To check for the first aspect, the significance of the estimated indicator weights is determined by means of bootstrapping (Chin, 2010). In order to check the second case, the variance inflation factor (VIF) can be used for such tests. As a rule of thumb, a VIF greater than ten indicates the presence of harmful collinearity. The values presented in the table 1 shows values lower than 1.4. Figure 1 shows the CFA results.

Content validity was established through a review of the existing literature, by selecting measurement items already validated in previous studies, and through personal interviews with experts from the four industries studied (Hair et al., 2016; Ferreras-Méndez et al., 2022). Four experts were interviewed from each sector: ceramic tiles, toys, and footwear. The interviews confirmed that the questionnaire items were fully understandable in the context of the industries analysed.

Table 1 presents the factor correlations, means, standard deviations and discriminant validity analysis. The discriminant validity index indicates the extent to which a construct is different from other constructs. For assessing discriminant validity, we used Fornell and Lacker (1981) criteria in which the AVE must be higher than the squared correlation between the constructs (Henseler et al., 2009). According to the values in Table 2, the above condition is met in all cases.

Figure 1: CFA of innovation capabilities.

| Factors | Weights | T-stadistic | Tolerance | VIF |

|---|---|---|---|---|

| Technology capability | 0.411*** | 18.416 | 0.713 | 1.424 |

| Marketing Capability | 0.590*** | 20.741 | 0.702 | 1.402 |

| Design Capability | 0.236*** | 7.546 | 0.837 | 1.194 |

Before testing our hypotheses, we assessed the extent of common method variance by conducting a Harman’s single-factor test (Podsakoff and Organ, 1986; Podsakoff et al., 2003; Bou-Llusar et al., 2009). Common method variance is a problem that can arise when the dependent and independent variables are collected from a single informant. In our study, we used two different key informants to minimize this problem.

3.4 Test of Research Hypotheses

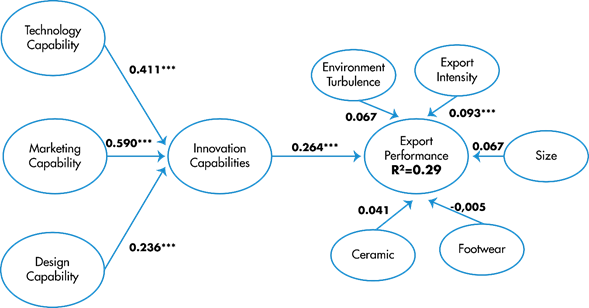

We used structural equations methodology (SEM) with the method offered by PLS software to test our hypotheses. SEM has been developed in a number of academic disciplines to substantiate theory. SEM allows for the inclusion of latent variables that can only be measured through observable indicators. In this study, concepts such as Innovation Capabilities are difficult to observe. Furthermore, SEM assesses measurement errors and allows all the relationships proposed in the conceptual model to be estimated simultaneously (Hair et al., 1998; Bou-Llusar et al. 2009). Figure 2 shows the results.

As it can be seen in Figure 2 and table 3, innovation capabilities is a second order construct formed by three first order constructs: technology capability, marketing capability and design capability. The 29% of the variation in export performance is explained through innovation capabilities.

Table 2: Factor correlations, means and standard deviations and discriminant validity analysis.

[i] Note: diagonal elements (in parenthesis) are the square root of the AVE; off-diagonal elements are the correlations among constructs in the inner model.

Concluding

4. Discussion and conclusions

Innovation and exports have received a great deal of research attention in recent years. These are issues of paramount importance for SMEs. Although innovation is generally considered to have a positive impact on export performance, the capabilities required to develop successful innovations need a broader perspective that fully integrates design activities. In our research, we found that innovation capabilities can be understood as a set of three main capabilities: technology, marketing and design. We also found that these innovation capabilities boost export performance in the context of manufacturing SMEs. From an RBV perspective, our findings make an important contribution to innovation as well as to international business literatures.

Our study contributes to the literature on innovation by providing evidence of the importance of design capabilities. The importance of design activities has often been understudied in favour of technology and marketing activities. Our finding is especially important for firms that operate in a context in which marketing and technology management are important but not so determining. This is often the case of low and medium technology manufacturing SMEs. They might address a market that is rather mature and therefore does not change so often. They typically lack a proper R&D department and therefore are not used to have an avant-garde positioning in technology issues. However, they might succeed in achieving outstanding design products with a rather restrained design budget.

Our findings also represent a contribution to international business literature by providing a new and more complete picture of the narrow relationship between innovation and exports in the context of SMEs. Technology, marketing and design capabilities might be considered as an important determinants of export performance These findings are important also in terms of competitiveness because we are witnessing that in all contexts, but especially in regions in recession, exporting is vital for SMEs since it normally implies increasing turnover in non-recession regions in which international sales are more likely to be paid on time than in domestic sales.

This study has interesting implications for practitioners. Our findings provide a general guideline to managers on how to make the most of their resources, especially in a context of economic difficulties. Developing technology, marketing and design capabilities is likely to increase the company’s export performance, which in turn is positively connected to competitiveness and a balanced financial situation.

Because SMEs face important resource endowment limitations, some firms might not be excellent in all three innovation capabilities. From a dynamic point of view, our suggestion for those firms would be to focus on the innovation capability that is more determinant at present. Then, formulate and establish a plan to develop through time the other innovation capabilities.

Technological capability could be the most demanding capability in terms of resources. However, it should not be forgotten since it likely to have very important effects in terms of value creation in the long term.

Finally, our results must be viewed in the light of the study’s limitations. All data were gathered in 2011-2012. Since it is a cross-section analysis, we have not considered the required time that innovation capabilities would need to impact on the company’s export performance. This research is based on three different industries in Spain. Even if they are quite representative of Spanish SMEs extrapolating conclusions for other manufacturing industries should be done with caution. Further research is required to consider the time effect between the variables of this study and to carry out these analyses in other industries.

Acknowledgements

Acknowledgements

Authors acknowledge the financial support of the Spanish Ministerio de Innovación, Ciencia y Universidades (PGC2018-097981-B-I00) and Ministerio de Ciencia e Innovación (PID2021-127882NA-I00).

References